About Us

Family-Owned. High-Tech. Built to Deliver.

From stainless steel to aluminum and mild steel, M3 Fabrication specializes in creating durable, precision-made components with a powder coat finish, whether it’s a one-off piece or large-scale production.

Our owners’ hands-on approach ensures top-notch quality and personalized service, making us the trusted partner for both local and out-of-state clients. We’re committed to excellence, competitive pricing, and reliable delivery… so you can trust us to bring your vision to life.

From Dream to Reality

M3 Fabrication was founded in March 2014 by brothers Tyler and Sam McClure, with guidance from their father, Phil, who had a successful concrete business in Denver, Colorado. When homeowners began requesting covers for precast egress window wells, the McClures saw an opportunity to create a product and build a business to meet that need.At the time, Tyler was working as an engineer at a local agricultural machinery plant that outsourced its fabrication work. Recognizing a gap in the market for custom racks, the McClures consulted family friend Jack Boatman, who helped them tap into a network of businesses needing high-quality fabrication services. Sam, studying Industrial Technology in college, was eager to join the business, and together they launched M3 Fabrication.

From that point forward, the McClures have driven M3’s success by staying committed to craftsmanship, innovation, and the pursuit of excellence.

The McClure Brothers

Sam McClure (GO, GO, GO), right, and Tyler McClure (WHOA, WHOA, WHOA), left, share a passion for solving complex fabrication challenges.

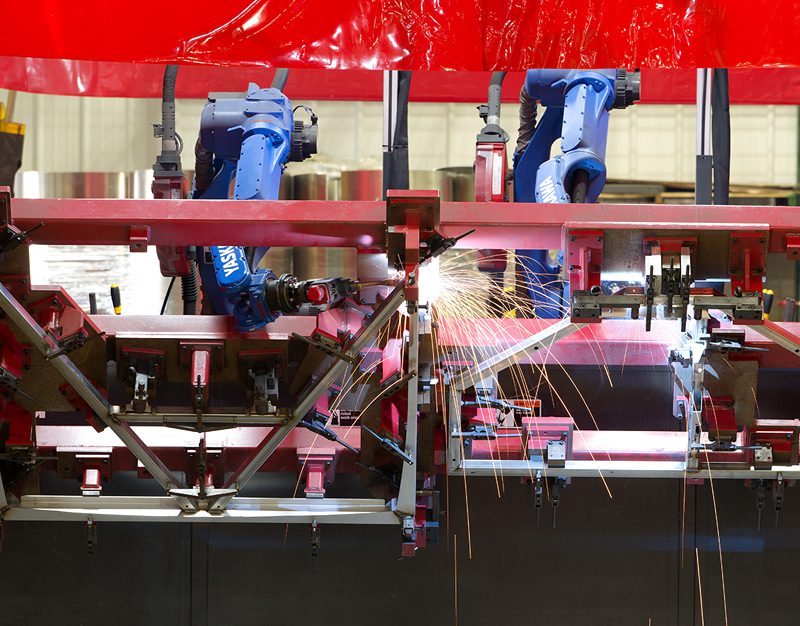

State-of-the-Art Facilities

The McClure's insistence on staying up-to-date with emerging technologies in their industry ensures the highest quality on each and every job.

The Expansions

In October 2013, M3 Fabrication broke ground at the Bloomfield Industrial Park, with both McClure brothers getting hands-on with the concrete footings, walls, and floors. The 14,500 sq ft building was completed, and by March 2014, M3 shipped its first government contract for carts.As demand grew, so did M3’s capabilities. We expanded our original building by 10,500 sq ft to accommodate powder coating, welding, and additional work-in-progress space. The next phase saw a 15,000 sq ft wing added, creating room for our stainless steel division, enhanced shipping facilities, and improved manufacturing processes like machining, laser cutting, and robotic welding.

Our expansion continued with the addition of a 7,000 sq ft Tube Shop, dedicated to cutting tube, angle, channel, and bar products. We also acquired the former Davencorp Welding facility just two blocks away, gaining 50,000 sq ft of space and rebranding it as M3 Fab West. With state-of-the-art equipment and facilities, we remain at the forefront of industry technology, delivering top-quality craftsmanship with every project.

And we’re just getting started—we’re glad you’re here to be a part of it.

Company History

OCTOBER

2013

Groundbreaking on new building construction

MARCH

2014

First order is shipped

DECEMBER

2015

New building addition of 10,500 sq ft

OCTOBER

2016

New fiber laser system implemented

JUNE

2018

Groundbreaking on new 14,500 sq ft stainless steel division

JANUARY

2019

Stainless steel division is completed

JANUARY

2019

Added robotic welding to our capabilities

APRIL

2020

ISO 9001:2015 Certification completed

MAY

2022

Purchase and acquisition of Davencorp

APRIL

2023

2 new 10k lasers and 1 stainless/aluminum laser implemented